The world of kitchen knives at WÜSTHOF is wonderfully diverse. There are knives with small, nimble, three-inch blades and large, powerful, twelve-inch blades. Handles might be crafted from sustainably sourced African Blackwood or patented, cutting-edge technology like the Hexagon Power Grip. There are utility knives and cleavers, knives for trimming and knives for boning, and knives for budgets large and small. Another key variation within our blade range is the difference between forged and non-forged knives.

Differences Between Forged and Non-Forged Knives

Forged Knives:

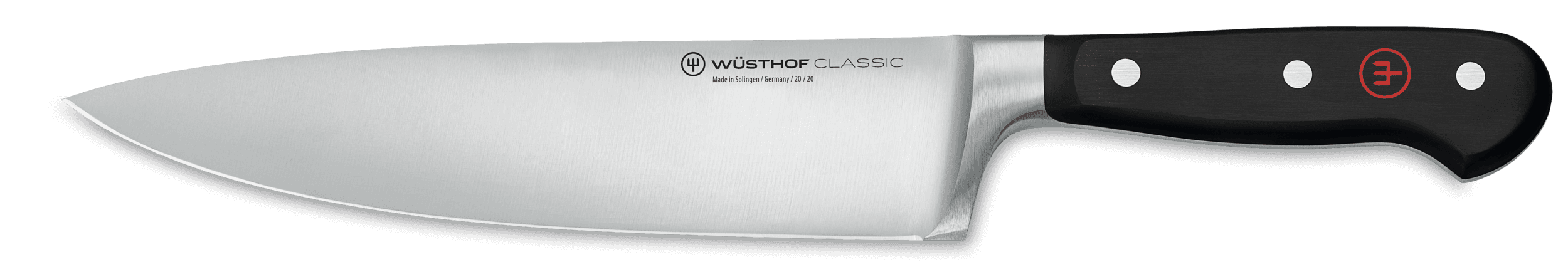

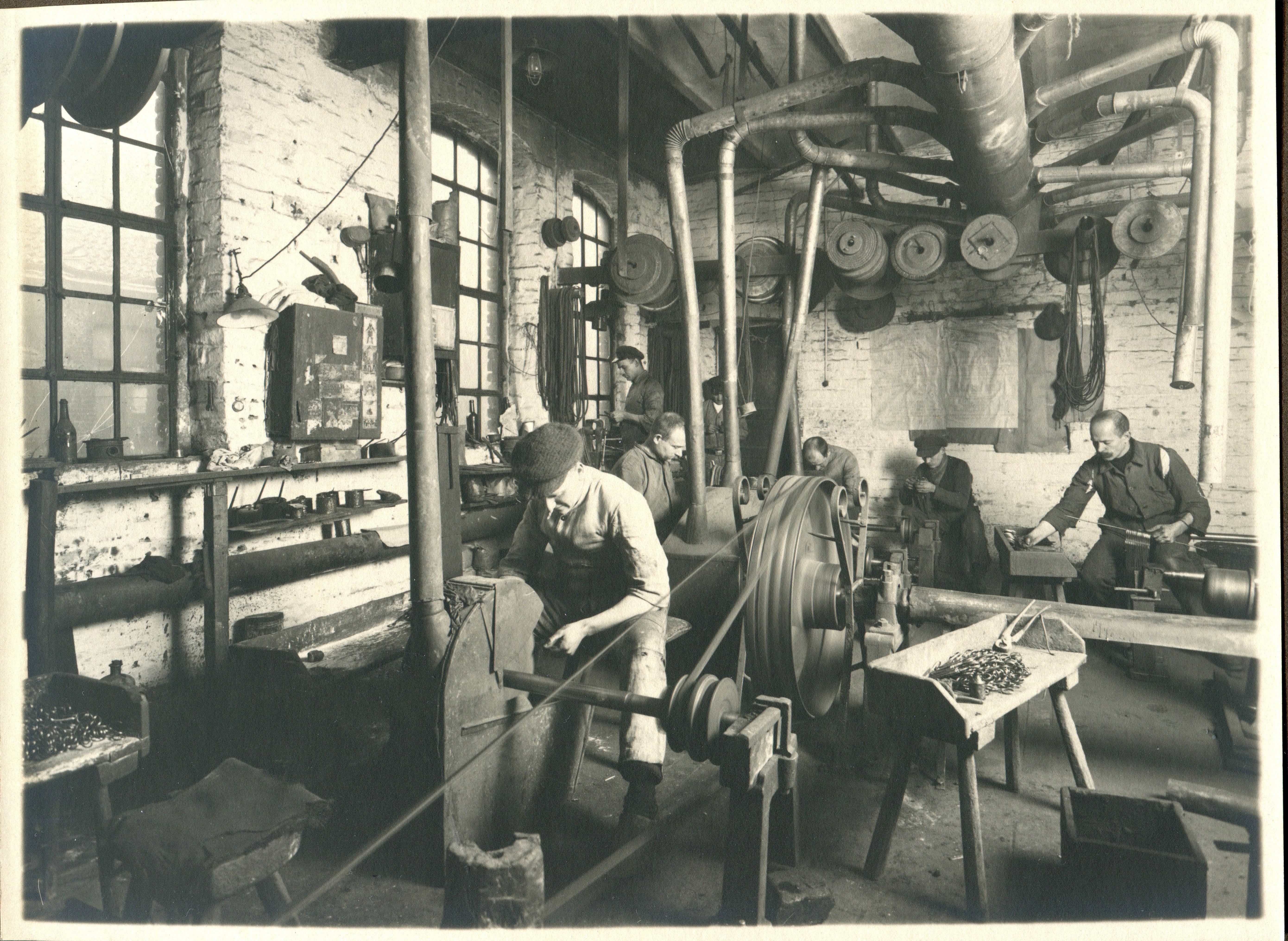

WÜSTHOF’s forged knives have been world-renowned for over two hundred years for a reason. These blades are often recognizable by their bolster — the thicker junction between the blade and the handle — which gives them a distinctly balanced weight. At WÜSTHOF's production factory in Solingen, Germany, forged knives are meticulously crafted through a process involving over fifty-four manufacturing steps. This process seamlessly blends innovative technology with the time-honored traditions of hand-made artisanship.

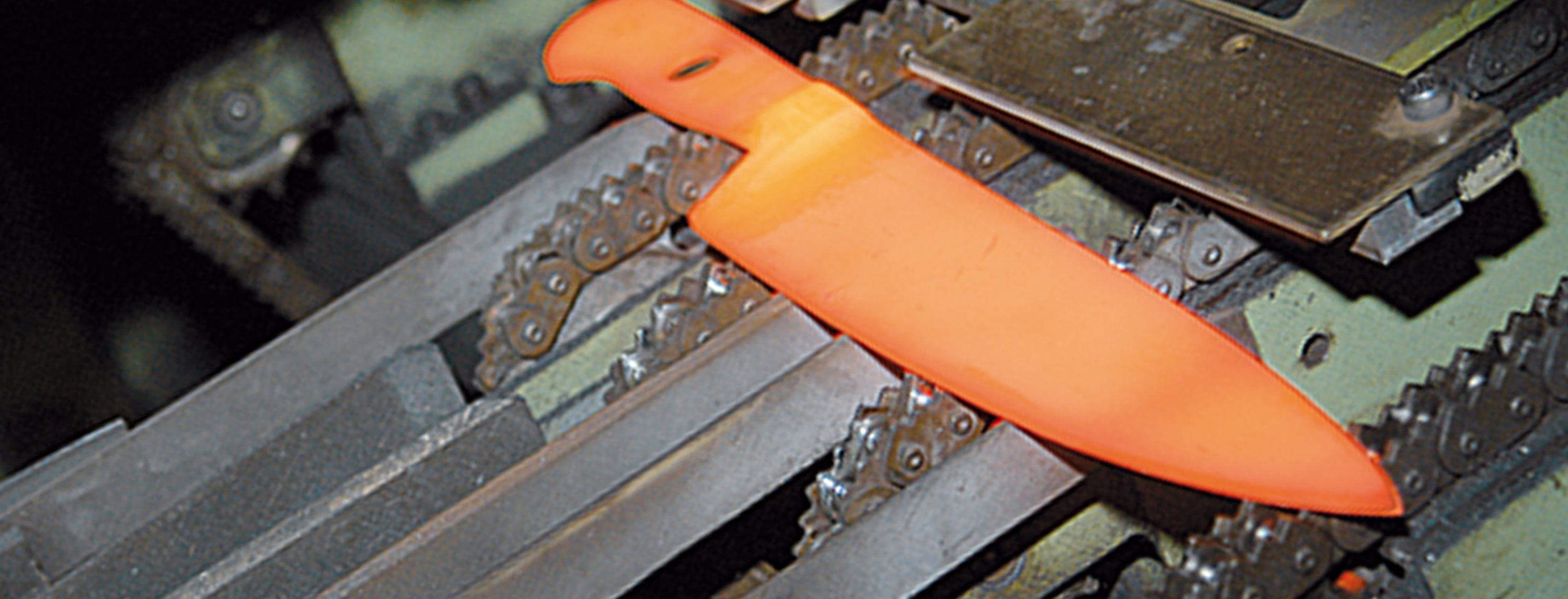

A forged knife is crafted by heating a single piece of specially formulated WÜSTHOF steel to over 2000°F and shaping it in a compression forge to achieve the desired shape. The steel is compressed in the forging system, tempered, and hardened to a unique 58 Rockwell, rendering it exceptionally sharp, durable, and rust-proof while keeping it flexible and easy to re-sharpen. After hardening, the blade goes through dozens of phases including blade-honing, dry-fining, and handle assembly. Finally, each WÜSTHOF forged knife is finished with precision-laser sharpening and a final polish by hand. In short: forged knives are the highest industry standard for long-lasting, premium blades.

Hardening Process

The process of hardening steel to the ideal 58 HRC occurs in three key stages.

Special Steel

The knives are crafted from one piece of stainless steel.

The Bolster

Forged knives are recognisable from their bolster, the thickened section between the blade and handle.

Non-Forged Knives:

Non-forged knives are lightweight, agile, and just as sharp as their forged counterparts. Since the blades are not forged, the production process is somewhat less intensive — though not much less vigorous, thanks to thirty-five manufacturing steps. In addition, over twenty quality controls continue to ensure WÜSTHOF’s superior standards.

First, unfinished blades are cut from a high-quality steel sheet using a precision laser. The rest of the production process mirrors forged blades, with hardening, honing, dry-fining, handle assembly, and a final polish by hand. With a hardness between 55 and 57 Rockwell, their robustness is comparable to forged blades: durable, rust-resistant, extremely sharp, and high performing. The key difference is in the bolster — non-forged knives don’t have one, which lends to their lightness and easy maneuverability.

Steel Hardness

WÜSTHOF's non-forged knives have an HRC (Hardness Rockwell) between 55 and 57.

No Bolster

Laser-cut knives do not have a bolster, meaning there is no thickened section of steel at the point where the blade and handle meet.

This is a good time to remember WÜSTHOF’s overall knife motto: there is no universal, perfect knife, just the perfect knife for you. Perhaps you are a seasoned home cook who would like to invest in a timeless, long-lasting knife that you can pass on for many generations — a forged knife from the Classic series would be a great place to start. Maybe you’re a recent graduate who wants an excellent knife at a more economic price point, plus a lighter weight for getting started in the kitchen — in that case, why not peruse the non-forged Gourmet series? The variety within WÜSTHOF’s kitchen knives (which, we admit, we think are all perfect) means that no matter what you’re looking for, the best knife for you is within reach.

Related Posts

Legacy

A Brief History of Knife Production

Knife Knowledge